Services

Li-ion battery materials development, testing, and failure analysis

Hands-on-training for battery fabrication, operations, and data presentation

Data management to unite electrochemical and experimental data for rapid data analysis

Compliance with ISO and automotive quality standards

Battery Consulting

Biomaterials, electronic materials, ceramics, metals, plastics, composites

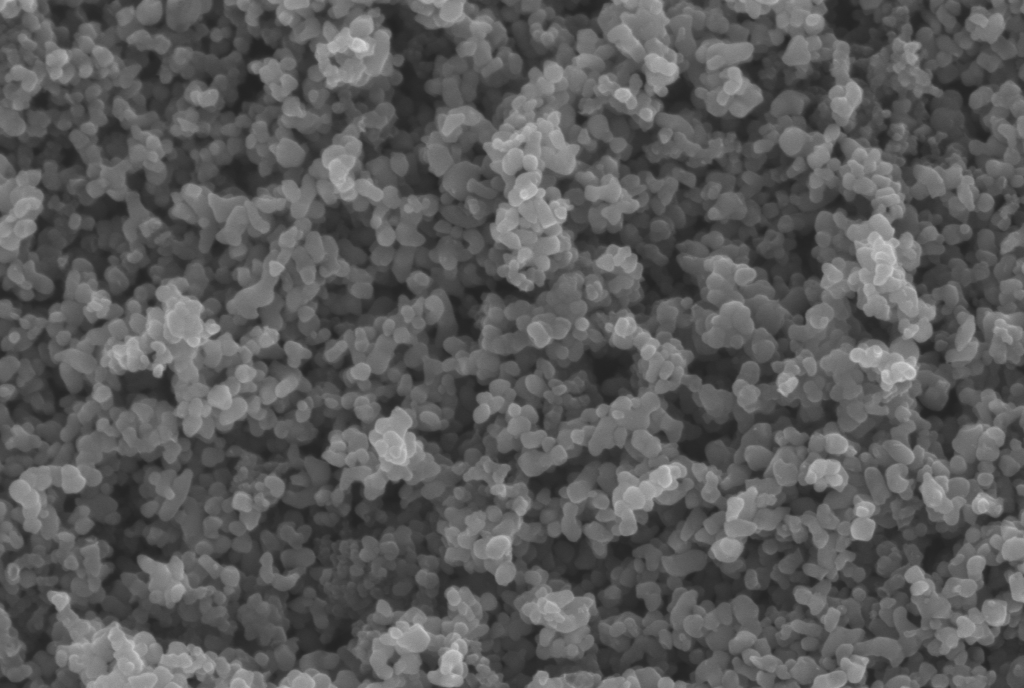

Scanning electron microscopy (powder, thin film, cross sectional analysis, EDS)

X-ray diffraction (powder, thin film, single crystal)

X-ray photoelectron spectroscopy (survey scan, high resolution, depth profiling)

Materials Characterization

Third party validation

Corrective action planning

Hypothesis testing

Non-linear problem solving to identify issues during development or production

Root Cause Analysis

Actionable practices for chemical and electrical hazard mitigation

Work instructions developed from chemical SDS and instrument documentation

Onsite deployment to meet scale and budget

Incident investigations and corrective actions